Industrial vision

Seizing new opportunities in flexible vision and Deep Learning for industrial production

Our customers’ challenges

Innovation

Are you looking to innovate and need to complement your teams with new, complementary expertise?

Solution

Are you looking for a product that offers you flexibility and a high level of performance for your vision processing?

Turnkey software

Are you looking for an experienced partner to automate your controls with vision, taking advantage of the benefits of Deep Learning?

Expertise at your service

Manufacturers are faced with the challenges of precision, speed and quality in their production lines. Manufacturing defects, traceability errors and operational inefficiencies can lead to significant costs and affect a company’s reputation.

Adopting a proactive approach and taking advantage of the new opportunities offered by flexible vision and Deep Learning are essential leverage arms for your competitiveness.

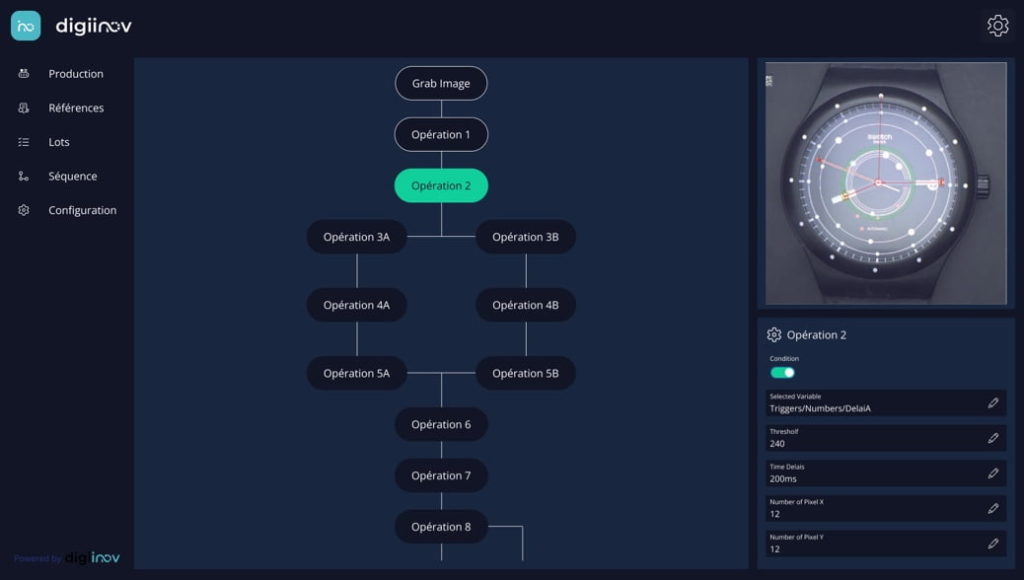

Recipe Vision No-Code

Implementing machine vision systems has traditionally required specialized technical expertise, often making adjustments and system evolution slow and costly, especially in fast-moving production environments.

Digiinov redefines vision system implementation with a revolutionary No-Code approach. Our solution enables operators to create and modify vision recipes without the need for specialized programming skills, making the process faster, more flexible and accessible. We provide intuitive interfaces and visual tools to facilitate the configuration and adaptation of vision systems, ensuring that most production changes can be managed agilely and autonomously.

KEY WORDS

- Vision No-Code

- Autonomy

- Extensibility

- Quality control

- Fault detection

USE CASES

- Production changeover

- Add a new product

- Optimizing quality control

Aesthetic control using Deep Learning

Aesthetic control of products in production is critical in some areas to maintain high quality standards. Until recently, technology was too limited to offer the same level of control as humans. Deep Learning vision has changed the game.

At Digiinov, we use Deep Learning to transform aesthetic inspection into a more precise, reliable and repeatable process. Our deep learning models are fine-tuned on images of your products to learn and recognize your quality standards, ensuring a match with your expectations to optimize your quality controls.

KEY WORDS

- Deep Learning

- Aesthetic control

- Industrial vision

USE CASES

- Fault detection

- Quality certification

- Industrial optimization

OCR and QR reading on industrial parts

Accurate traceability and identification of products throughout the production chain are essential in certain industries to guarantee quality, compliance and logistical efficiency. However, manual reading on industrial parts can be complex, tedious and error-prone.

Digiinov offers an advanced OCR and QR code reading solution to automate and make reliable the identification and tracking of industrial parts. More information on the DigiOcr page.

KEYWORDS

- OCR

- QR Code

- Intuitiveness

- Performance

- Personalization

USE CASES

- Traceability

- Duplicate detection

Centralized vision processing

Today’s industries rely increasingly on machine vision for various aspects of production. However, managing multiple vision systems spread across different machines can lead to challenges in terms of integration, licensing costs, data consistency and maintenance.

Digiinov has expertise in centralizing vision processing. This approach transfers CPU processing loads from individual machines to a powerful, specially-equipped central server, optimizing performance and reducing hardware costs on production lines. What’s more, this centralization facilitates easy scalability, enabling vision processing to be added and updated from a central point without requiring intervention on each machine individually.

KEYWORDS

- Centralization

- Extensibility

- Performance

USE CASES

- Centralized image processing

Industrial applications

About Digiinov

Industrial IT expertise

Digiinov is a leading engineering company in French-speaking Switzerland, bringing together rare, cutting-edge expertise in the creation of technological solutions for industrial digitalisation and automation.

Strong intervention capacity

Our team is made up of around twenty employees. We’re essentially engineers whose driving force is to make a big impact with our customers and accelerate your software projects.

Geographical proximity

We maintain close relationships with our customers, which enables us to develop an efficient and sincere collaboration as well as to intervene rapidly on site as required.

Contact us

Do you have a challenge with machine vision?

Don’t hesitate! We’re here to help you turn your ambitions into reality!

It increases accuracy, reduces errors and optimizes operations by providing automated quality control and real-time analysis.

In principle, yes. However, thanks to our No-Code approach, even non-technical users such as method specialists have a certain level of autonomy to improve the program or add new products.

Integration time varies from a few weeks to several months, depending on the project. Our solutions and expertise speed up the process, from feasibility to industrialization.

Most visions projects start with a feasibility study, enabling us to validate the capabilities of our technologies for your specific case.